First, the overall technical status and application status of graphene materials

The graphene industrial chain includes upstream, midstream and downstream, upstream for the production of various raw materials used in the production of graphene, such as graphite, hydrocarbons, etc., the midstream is the study of various graphene materials, including graphene film, graphene powder Body, etc., downstream is the development of graphene end products.

From the research and development of various countries, the United States has covered the entire chain from the mining of upstream graphene raw materials to downstream specific industrial applications. The results of European basic research are abundant, but the industrial application links are weak. Japan and South Korea are concentrated in downstream industrial applications. Especially in the field of electronic devices, the application results are rich. China has abundant graphite resources, and has realized industrialization in the large-scale production of graphene raw materials and conductive additives in some downstream areas such as coatings and batteries. However, the downstream applications are still concentrated on products with lower added value and high added value. Product progress is weak.

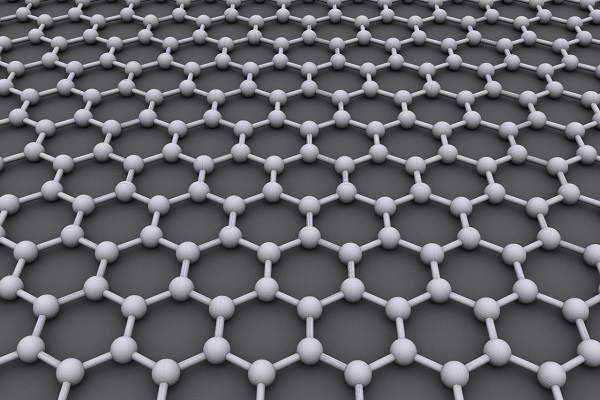

At present, the key issue in the development of the graphene industry is the preparation of high-quality graphene. Combined with the relevant policies of various countries, it can be seen that the focus of research and development in the future is the study of graphene materials in the middle of the industrial chain. Currently, graphene preparation methods mainly include mechanical stripping, liquid phase stripping, epitaxial growth, chemical vapor deposition, and redox.

In downstream industrial applications, graphene applications mainly involve electronic devices, optoelectronic devices, energy, composites, biomedical and environmental fields. In the field of electronic equipment, graphene has been applied to electronic devices due to its excellent electrical properties. At present, field effect transistors for high-speed action RF circuits using graphene in the channel layer have been developed. A transistor and an inductor using graphene as a channel and a mixer IC having a working bandwidth exceeding 10 GHz are integrated on the wafer. In the energy field, the excellent conductivity of graphene can greatly increase the output power density of the battery. The charge and discharge rates of lithium-ion batteries and supercapacitors prepared by graphene are much higher than those of ordinary batteries. In the field of optoelectronic devices, transparent conductive film is one of the most practical applications. Graphene can be used as an alternative material for ITO, for touch panels, flexible liquid crystal panels, organic EL illumination, etc. It is reported that graphene capacitors for mobile phones are currently reported. The touch screen has been developed successfully. The graphene-based composite material has greatly improved the mechanical strength, thermal conductivity and adsorption of the material. It is optimistic that it is a cable material for the production of “Cosmic Elevator”, and has recently been promoted for heat dissipation. In the field of biomedicine, research on graphene nanobiomolecular sensors has also made breakthroughs.

Second, domestic graphene material technology and application and foreign differences

From the research field of graphene materials at home and abroad, China’s research with foreign countries is indifferent, and even in some areas is at the leading level. By 2015, the number of research papers on graphene in China is the highest in the world. 34%, more than 19% in the United States. Compared with foreign countries, China has made breakthroughs in the growth and preparation methods of graphene materials, and the research level has entered the international advanced ranks.

From the perspective of large-scale production of graphene, China has been able to achieve large-scale production of graphene powder and slurry, which is comparable to foreign countries.

In industrial applications, China is currently concentrated in conductive heat-dissipating films (including heating clothing, physiotherapy products, etc.), battery conductive additives, heat-dissipating materials, and have achieved industrial applications. The developed economies such as Europe, the United States, Japan and South Korea are mainly concentrated in high-end fields such as optoelectronic components, sensors, medical and environmentally friendly materials. In contrast, China’s application of graphene in high-tech products is insufficient. For example, in the field of new energy batteries, The graphene battery technology developed by the United States has been able to reach a range of 643 kilometers in new energy vehicles and can be industrialized. However, although China’s new energy battery technology has made substantial progress, it has not yet been industrialized. In the field of coatings, China has vigorously developed the application of graphene in anticorrosive coatings, but the gap between salt and fog and rain erosion is more obvious.

Third, the current technical barriers to graphene materials

At present, the biggest technical bottleneck of graphene industrialization is that there is no high-quality large-scale production technology of graphene raw materials, and there are barriers to high-quality graphene (especially single-layer graphene) technology with large size and impurity defects controllable. The performance of downstream products is the main reason for the current lack of application of graphene technology in high-end electronic products. Although the quality of graphene obtained by mechanical stripping is high, the success rate is too low, and it is impossible to industrialize mass production. It is only suitable for laboratory research. Chemical vapor deposition can produce high-quality, large-area graphene, but it has an environmental impact. Larger, higher cost; oxidation and reduction methods are currently the most ideal method for large-scale production of graphene, but it will also lead to quality degradation.

The lack of high-quality graphene preparation methods also directly affects the application of graphene in the field of LED lighting. The current methods of using graphene heat dissipation mainly include the use of graphene sheets and graphene coating films. Graphene sheets are mainly prepared by chemical vapor deposition, but still do not solve how to prepare high-quality large-area graphene and how to achieve non-destructive transfer. It is better to remove a few layers of graphene by mechanical stripping, but the preparation efficiency is low. It is difficult to industrialize. The graphene heat-dissipating film can be prepared by a liquid phase stripping method, but the uniformity needs to be improved, and the redox method is likely to have an influence on the environment.

Graphene is a two-dimensional material that provides a large contact surface, strongly affected by interfacial interactions, atomic defects, and edges, with high in-plane thermal conductivity and relatively low external thermal conductivity perpendicular to the planar direction due to The van der Waals force between the multilayer graphene layers results in a large interlayer thermal resistance such that its thermal conductivity perpendicular to the plane direction is less than two orders of magnitude lower than the in-plane thermal conductivity, showing significant anisotropic heat conduction. The thermal conductivity of single-layer graphene is as high as 5200 W/(m·K), but the thermal conductivity of multilayer graphene varies with the number of layers. When the number of layers is 2-4, the thermal conductivity is rapidly reduced to 1300- 2800W / (m · K).

Fourth, the contribution of graphene technology to the LED lighting industry

Graphene has a wide range of applications in high-power LED lighting due to its excellent electrical and thermal conductivity. Graphene currently has three main application directions, using its conductive properties to make transparent electrodes or for transparent conductive layers near electrodes, using its thermal conductivity to prepare thermally conductive films, and coating a substrate with a heat-conducting heat-dissipating graphene coating. . In addition, there have been many studies on the use of graphene as a light-emitting layer material, as a lamp housing, as a transparent packaging material, and as a current diffusion layer.

In the field of electrical conduction, in recent years, gallium nitride-based light-emitting diodes (LEDs) have developed rapidly. In GaN-based LEDs, indium tin oxide (IOT) has become a transparent conductive in LED production process due to its high electrical conductivity and high light transmittance. The main material of the film. In April 2015, the Graphene Institute of the University of Manchester in the UK developed a new graphene bulb with a filament-shaped LED light source inside. The outside of the LED source is coated with graphene, which utilizes the conductivity of graphene to make the bulb. It takes longer to use and reduces energy consumption. The new graphene bulbs are still based on LED technology, which greatly enhances their performance and longevity through the magic of graphene molecules, and is expected to be cheaper than traditional LED bulbs.

In the field of illuminating, in July 2015, Ren Tianling, a professor of micro-nanoelectronics at Tsinghua University, used a two-form graphene to create a new luminescent material, which was first demonstrated in a graphene-based luminescence system. An LED can adjust the light of different colors, covering almost all colors of the entire visible spectrum.

In the field of lighting and heat dissipation, photoelectric conversion is realized by semiconductor chips in LED illumination. In order to maximize the conversion of electrical energy into light energy instead of thermal energy, and to improve the luminous efficiency of LED illumination, it is necessary to solve the heat dissipation problem of the semiconductor chip, and graphene The heat dissipation capability is very good. The thermal conductivity of the single-layer graphene film reaches 5.3 kW·(m·K)-1, which is much higher than the traditional technical materials, and is an effective means to solve the problem of heat dissipation of LED lighting.

Minghao (Beijing) Electronic Technology Co., Ltd. is a pioneer and a pioneer in the application of graphene heat dissipation in the field of LED lighting. Based on the integrated platform of production, education and research with Beijing University of Technology and Zhejiang University, it has strong new material research and development capabilities. Three kinds of graphene heat-conducting and heat-dissipating composite materials with reversible liquid crystal phase change characteristics (RLCP) have been developed, which are graphene in-situ curing thermal silica gel, graphene composite solid-liquid phase change material and graphene composite heat-dissipating reinforced coating. Solve three key problems in heat dissipation: heat conduction, temperature uniformity and heat transfer. Applying it to the heat sink structure of high-power LED lighting, the effective control of the junction temperature of the chip and the miniaturization of the heat sink are realized. On this basis, a series of LED lighting products have been developed, such as graphene cooling LED lighting module, graphene cooling LED lighting tube, graphene cooling mining lamp, graphene cooling LED tunnel lamp, graphene cooling LED car front Lamps and so on, especially the creative design of graphene heat-dissipating LED street lamp tube structure, subvert the traditional mode of LED street lamp industry, replacing the replacement method of the original lamp street lamp to replace the whole lamp head of sodium lamp. Through the standardized structural design, the plug-and-play replacement method can be realized without replacing the sodium lamp housing, and the labor cost and equipment cost are greatly reduced. It is expected to become the new development direction of LED street light standards.

In addition to Alum Technology, the Philips MASTER LED MR16 is the world’s first high-power LED application. Its aluminum casing has been replaced by Stanyl TC thermal plastic developed by DSM, which not only achieves the same level of heat dissipation. Purpose, and the entire luminaire is lighter and more resistant to corrosion. The thermal conductivity of graphene thermal conductive plastic can be increased from 0.2W/mK of ordinary plastic to 5-15W/mK, and it is resistant to corrosion.

Blue Stone has developed high-power LED products using graphene heat-conducting plastics and has demonstrated excellent heat dissipation. On the other hand, the heat dissipation performance of the heat-dissipating film made of graphene is much better than that of the graphite sheet, and the measured thermal conductivity can reach above 1000 W/mK, and the film has good flexibility and is easy to process.

The cooling module for LED lamps developed by Xiamen Taiqi Lifei Electronic Technology Co., Ltd. uses a thermally conductive polymer material mixed with graphene material to form a module to replace the existing aluminum heat dissipation module, and the practical use has limited improvement in thermal conductivity. Currently only available in low power (less than 30W) lighting radiators.

Shandong Jingtaixing Optoelectronics Technology Co., Ltd. uses graphene on the metal substrate at the back of the filament. The heat generated by LED heating radiates heat through the graphene, and uses the heat conduction gas in the shell to achieve effective convection and reduce the temperature. . According to the comparison between the graphene coated and the non-graphene products, it can be seen that the junction temperature of the graphene coated chip is 3-5 degrees lower than the junction temperature of the uncoated graphene, which does not contribute to the extension of the filament life.

The 2016 Global Graphene Industry Research Report released by China Graphene Industry Technology Innovation Alliance pointed out that in the next 3-5 years, graphene thermal film and graphene heating film will be rapidly commercialized; in the next 5-7 years, there will be New and practical graphene thermal conductive plastics and graphene thermal conductive coatings are used in production and life; in the next 7-10 years, there will be lighter and embedable graphene thermal conduction chips, which will improve heat dissipation efficiency. China leads the global development in this industry, and the market size will be multiplied by the annual growth rate of 200-300%.

The 2016-2021 China Graphene Industry Research and Analysis and Market Forecast Report released by the China Industrial Research Institute predicts the market scale of LED application of graphene thermal conductive film from 2016 to 2020. By 2020, the market scale of LED thermal conductive film can be It reached 1.25 billion.

Fifth, Breakthrough and innovation in graphene materials in recent times

In the preparation of graphene, scientists such as Moreno of the Institute of Nanoscience and Nanotechnology at the University of Catalonia have used chemical synthesis to prepare nanoporous graphene with precise position and use the material in semiconductor transistors.

Prof. Peng Hailin from Peking University proposed a new method for producing high-quality graphene without wrinkles. By growing graphene on the surface of crystallized copper with different atomic positions, smooth graphene is obtained to overcome the appearance of graphene in chemical vapor deposition. The problem of wrinkles.

In the preparation of single and few layers of graphene, Rokni. H et al. used a computer control system to simulate the predicted charge distribution, and controlled the thinning of the atomic thin layer material by an electrostatic method to obtain a single layer of graphene.

These high quality graphene preparation methods are all helpful to further enhance the application of graphene in the field of LED lighting.

In addition, in the application of graphene in LED lighting, RenliLiang et al. proposed the use of fluoropolymer containing graphene oxide or silicon-based composite material containing graphene oxide as interface sealant to realize LED encapsulation and improve deep ultraviolet luminescence. Diode efficacy and operational stability.

In the use of graphene heat dissipation performance, Gao et al., in view of the high non-metallic thermal conductivity material, has a high K value, but has poor flexibility. The high-temperature reduction oxidation method is used to obtain a highly flexible atomic film graphene, which maintains high thermal conductivity. Increase its flexibility on the basis of sex.

On graphene composites, CHO E C developed the use of graphene in polyamide fiber thermoplastic composites, which has a good heat dissipation effect on LED illumination.

Xi’an Jiaotong University found that single-layer continuous graphene has better heat dissipation effect by comparing the heat dissipation effects of various types of graphene on LED chips.

Sixth, Domestic company patent layout and intellectual property challenge

Graphene, the king of new materials, can promote technological leap and development in many industries. International technology and market competition also inevitably involve intellectual property disputes. Since 2015, China has been the world’s largest patent application for graphene technology. According to the analysis of the 2015 Graphene Technology Patent Analysis Report jointly issued by China’s Graphene Industry Technology Innovation Strategic Alliance in 2015, domestic graphene The patented layout of the application field is concentrated in batteries, supercapacitors and composite materials, while the patent layout in high-tech fields such as information storage, optoelectronic devices and sensors is weak.

Specific to the field of LED lighting, through the search of the cnipr search platform, the domestic company currently has a total of 315 patents related to graphene technology in the field of LED lighting, and the main directions involved are mainly on the heat conduction of the LED light source chip. In terms of heat dissipation, there are 262 patents related to the heat conduction and heat dissipation performance of graphene, accounting for more than 84%, which is much higher than the patent layout in other directions. It can be seen that the domestic enterprises’ application of graphene in LED lighting is too concentrated on the thermal properties of graphene, and does not fully exert the characteristics of light and electricity of graphene.

From the perspective of applicant types, the combination of domestic research institutions and enterprises is insufficient. The research of research institutions focuses on high-quality graphene preparation technology and high-value fields such as sensors and batteries, but the research in LED lighting field is insufficient. Some patents have been laid out in the field of lighting, but the number of high-quality technologies and high-value patents is insufficient, which also limits the technological development of graphene in the LED lighting industry.

High-quality technology is inseparable from the practical and powerful protection of intellectual property rights. The lack of technology has led to the domestic patents for graphene LED lighting, which are mostly protected terminal lighting products. However, there is no strong intellectual property protection for the core components of LED chips and power supplies. Just as ZTE’s experience in the United States, once foreign countries develop high-quality single-layer graphene preparation technology that can be industrialized, the layout of related patents on LED lighting chips, power supplies, and luminescent materials will severely limit domestic graphene LED lighting products. Development and growth.

Seventh, the breakthrough direction of future technology of graphene materials

Large-scale, high-quality graphene production technology with controllable impurity defects is the core of the development of the entire graphene material, and is also the key breakthrough direction.

At present, the application market of graphene materials is mainly concentrated in the fields of conductive heat-dissipating films (including heating clothing, physiotherapy products, etc.), conductive additives, and heat-dissipating materials. It is still not seen in the fields of higher-end integrated circuits, chips, display materials, etc. There are four main problems in mature products. First, the application in these high-end fields mainly relies on the performance of real single-layer graphene. The production process of graphene with an annual output of 30 tons of graphene is known as oxidation. The reduction method or the physical method is difficult to obtain batch-free single-layer graphene raw materials in batches, often three or even ten layers of graphene microchips, and it is necessary to disperse the method before each use, otherwise it is strongly agglomerated. The effect, often turned into a pile of graphite powder material, loses the performance advantages of graphene in electrical and thermal aspects. In order to overcome the phenomenon of agglomeration of graphene, it is necessary to solve the problem of dispersibility. Due to the hydrophobicity and chemical inertness of graphene, the dispersibility is lower than that of graphene oxide. The main treatment methods are physical dispersion and chemical dispersion. The method of physical dispersion is ultrasonic or strong agitation, which is uniform dispersion of graphene. The chemical dispersion method mainly includes graphene functional modification and in-situ polymerization. The in-situ polymerization method prevents the agglomeration by adding nanoparticles and expanding the graphene sheets through the nanoparticles, thereby increasing the spacing, but the problem of the method is that the nanomaterials and the composite matrix materials must have good compatibility. This requires a suitable solvent, which is difficult to select and has the risk of environmental pollution. The functional modification of graphene is to add small molecular functional groups by covalent and non-covalent methods, modify the surface groups of graphene, and improve the solubility and dispersibility of graphene. For example, by oxidation, the surface contains carboxyl groups. The hydroxyl group is subjected to a silylation treatment by adding a silane coupling agent, and the graphene is modified by a polymer polystyrene sulfonate, and the graphene sheet layer is prevented from agglomerating by a non-covalent bond therebetween. In addition to the addition of small molecules, the graphene surface can be physically modified, for example by ionic liquids. In addition to the above methods, it is also possible to achieve dispersion of graphene by adding a dispersant and charge attraction to avoid agglomeration.

The second problem is how to overcome the application defects caused by the anisotropy of graphene. For example, in the field of heat conduction, graphene heat conduction is mainly limited by their application environment and relatively weak van der Waals force between layers, by designing graphene. The three-dimensional structure and composite materials can adjust the thermal properties, which is beneficial to the full utilization of the high thermal conductivity of graphene in heat dissipation applications and the low thermal conductivity in thermoelectric applications. For example, by preparing a carbon nanotube-graphene network (PGN) structure, a three-dimensional graphene structure such as a graphene-joined graphene sheet, and utilizing the advantages of both graphene and carbon nanotubes, a new generation of nanometers capable of adjusting thermal conductivity can be obtained. Materials, this new material has a high surface area, and the thermal conductivity of these three-dimensional structures can be adjusted by the distance between the lateral carbon nanotubes and the distance between the layers of graphene sheets, which can be widely used in supercapacitors, fuel cells, etc. . In addition, in addition to the immature production process of batch single-layer graphene, the transfer of graphene is also a big problem, because single-layer graphene is almost transparent and less than one hundred thousandth of the thickness of hair, so it is prepared. Single-layer graphene, how to transfer it is also very difficult, which is the third problem that needs to be faced in the marketization of graphene technology. The future solution is to integrate application and preparation, for example, directly depositing single-layer graphene in glass by CVD method. The surface of the screen enhances the surface conductivity without affecting the light transmission. The preparation method of this conductive screen is a typical case of preparation integration. Following this thinking, it is possible to use chips, integrated circuits and flexible in the future. Breakthroughs in areas such as display.

The fourth problem that needs to be solved in the marketization of graphene technology is the commercialization of “graphene+”. Simply put, the value of graphene composites in different industries is reflected. The biggest dilemma in this part of the application is that the application of most graphene addition modification does not reflect the irreplaceability and high cost performance of graphene. For example, graphene has many advantages in terms of conductive addition, thermal conductivity enhancement, etc., although it will increase the performance of the base material after the addition. However, due to compatibility and dispersibility, it may cause other performance degradation, resulting in a loss of gain. The results; or although showing a certain enhancement effect, compared with similar additives such as carbon fiber and carbon nanotubes, did not show obvious advantages, resulting in the loss of commercial value.