Recently, ROHM (headquartered in Kyoto, Japan), a world-renowned semiconductor manufacturer, held the annual “ROHM Lantern Festival” in the area around Kyoto headquarters. This event has ushered in its 20th year this year and has become the largest lighting feast in Kyoto. With the theme of “Sharing a Light Feast and Sharing the Emotional Moment of the Heart”, from November 22 to December 25, during the one-month period, about 860,000 colored lights illuminate Kyoto, bringing warmth to Kyoto’s winter. The wonderful time of the heart.

Highlights of the 2018 “ROHM Lantern Festival”

One of the highlights is the annual “University A cappella concert”. There are 47 groups of a cappella ensembles from 11 universities in the Kansai region of Japan. They performed 8 performances a day and performed 94 performances during the event. It is the largest a cappella performance in the Kansai region. The lights on the lawn square and the songs of the students together create a dreamy sound and light situation, and a special time to heal the soul.

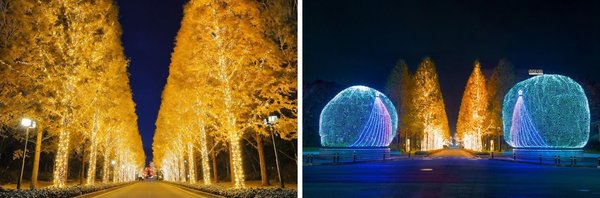

In addition, the lighting of the lawn square this year is also newly renovated. People can enjoy the dynamic lighting show “Glorious Cocktail Garden” by LED strips (about 1 meter high) embedded in the lawn and large LED screens (6 meters high x 12 meters wide), spreading like ripples The light that comes in, the space that continues to extend into the distance, echoes with the music, and is as beautiful as it is beautiful.

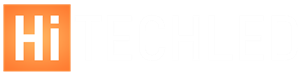

In addition, as the symbol of each Lantern Festival, the “Mountain Peach Tree” and the “Sparkling Trail” filled with the dreamy atmosphere make the Lantern Festival bright and beautiful. Visitors to Kyoto for sightseeing may wish to experience the experience on the spot.

Create a ROHM LED for the lighting feast

The LEDs used in the Lantern Festival are produced by ROHM. ROHM has been engaged in industry-leading product development for 45 consecutive years since it began producing in-line LEDs in 1973. Regarding the ROHM LED products that are essential for the Lantern Festival, engineers at ROHM LED Manufacturing said: “It can be said that the biggest advantage of ROHM LEDs is the comprehensive and strict quality management and the use of vertical integration production system (from the component manufacturing stage). At the beginning, we strictly implemented the product concept and independently developed products. In the LED development process, we always adhere to the ROHM’s quality first corporate philosophy, such as the use of chip design that is easy to manufacture in the assembly process, and implement traceable management of ultra-small products. Process management is carried out in accordance with the quality requirements of vehicle-grade products. ROHM attaches great importance to production technology and quality management, so that it can provide customers with original LED products that are miniaturized and highly reliable, and meet the diverse needs of customers.”

At present, ROHM’s LED featured products mainly have the following three types.

The first is a miniaturized, thinned LED product. As applications such as consumer electronics devices become smaller and smaller, the requirements for miniaturization of components have never stopped. Using ROHM’s original production technology, the component itself is miniaturized, and the position of the gold wire of the connecting component and the PCB board is reduced, and the thickness is only 0.2 mm, reaching the industry leading level.

Secondly, LED products that significantly reduce the brightness deviation of LEDs and successfully achieve stable brightness. It is very suitable for the application of LEDs side by side in automotive instrumentation and industrial equipment. Since the product concept and quality requirements are strictly implemented in the component manufacturing stage, the customer no longer needs to adjust the brightness uniformly, which is very helpful to reduce the design burden of customers. .

In addition, LEDs with excellent durability are also unique features of ROHM. For applications such as automotive brake lights that are used in harsh environments, ROHM is the first product in the industry to achieve a leap in anti-vulcanization performance in order to prevent problems such as reduced brightness due to aging of products.

In addition, there are small LED products that can effectively prevent light leakage from automobile meters. With the diversification of customer needs, ROHM’s product lineup is also expanding year by year.

However, these product developments have not been smooth from the start.

According to the engineer: Nowadays, “LED has a long life, and the brightness is uniform and bright after use for many years” has become a consensus, but to ensure and improve the reliability of LEDs, especially in outdoor use, the whole development The process is very difficult. For example, in a low-temperature environment in winter, the LED components will deteriorate rapidly after only one year of use, and the light of the high-brightness red LED elements will become dark after being damp, and the light of the white LEDs will turn yellow, etc., which will not occur in indoor use. occur. Despite the difficulties, the team members worked together to solve the problems and finally developed the unique ROHM products mentioned above.

With reliability advantages, products go global

Today, LEDs have become an integral part of our lives. Not only automotive taillights, but also digital displays and indicator lights for display panels of various devices in the field of automotive instrumentation, environmental lighting, industrial equipment, and functional displays in the field of consumer electronics, LEDs have been widely used in various applications. The demand for LEDs will increase further in the future.

According to the engineer, “In recent years, especially in the automotive and industrial equipment markets, the requirements for ‘reliability’ have become higher and higher. ROHM has always adhered to the principle of “quality first” and adopted a vertically integrated production system to ensure reliable products. Sexuality has played a huge role. In addition, refined services and technical support for customer needs are also crucial. In the future, ROHM companies will strive to develop new products for applications that value added value such as reliability and design. .”

In semiconductor technology, the most familiar product is LED. For example, in the colorful and beautiful lanterns that create one of the winter’s fun, many of the things we inadvertently see and use every day are products that rely on these semiconductor technologies. As a comprehensive semiconductor manufacturer, ROHM will continue to promote advanced product creation and make greater contributions to society in the future.